High-pressure Water Deburring System

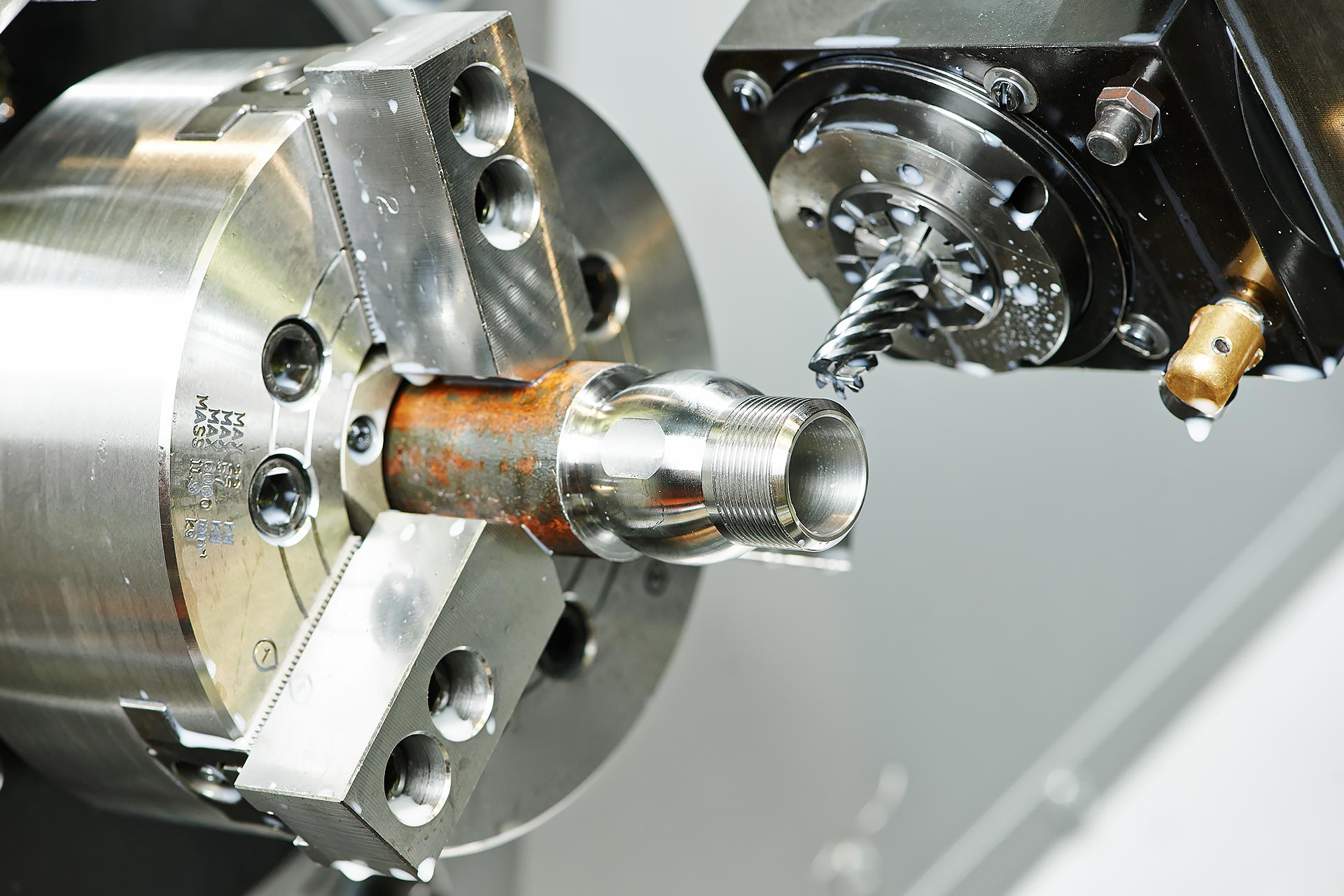

In the current processes of metalworking and machining of mechanical components, excess metal residues such as burrs and flash are produced during processes such as die-casting and cutting, which do not meet product requirements. Edge quality has a significant impact on the shape, performance, and lifespan of a product. Burrs and protruding edges can greatly affect the assembly of machine parts, such as gears, rollers, and other sliding surfaces, and can cause chain damage. They are crucial for precision components used in aviation, automotive, and electronics industries. Removing burrs is necessary to avoid compromising the quality and precision of the finished product.

Compared to parts without burrs, products with burrs have significantly reduced fatigue life. At the same time, burrs also pose a safety hazard, as sharp edges can puncture pressurized circuits and wires, and can cause injury to those handling them. If these burrs are not removed, they can cause trouble during the machining process and even affect the accuracy of the processed product. In such cases, high-pressure water jet cleaning can be used to clean hard-to-reach crevices and drill holes, relieving the parts that are difficult to handle manually.

High-pressure water jet technology in high-pressure cleaning can be applied to mechanical parts, aluminum alloys, cast iron, etc., using the powerful impact force of high-pressure water jets to remove burrs, scales, and other debris. It does not damage the surface of the workpiece, and does not require secondary cleaning or the use of chemical agents, which eliminates concerns of environmental pollution. It is widely used in CNC machining, aluminum production, foundries, mold factories, and other fields. The high-pressure cleaning system of the water jet can not only quickly and reliably remove burrs from machined edges, but also remove other impurities attached to the workpiece.

Pumpson can customize the high-pressure deburring equipment according to customer needs. Through a customized nozzle system for adjustment and calibration, the goal of removing burrs and cleaning can be achieved. By utilizing effective deburring technology, workpiece accuracy can be improved, and potential hazards can be reduced.